The question of expected yield per bit is one that every cutting tool salesperson and customer service specialist in the tooling business has been asked hundreds, if not thousands of times. While an approximate range/number can be provided in response, it requires the caveat that anticipated yield is based on the presumption that all outside factors that influence tool performance are optimal, so the tool itself can cut as intended. Excellent tool performance is the sum of the following: a machine spindle in good condition, a precision clamping system, effective material hold-down, efficient dust extraction, the use of proper machining parameters and a precision, balanced, high quality tool, working together, synergistically.

Presuming the machine spindle is calibrated and in good shape, the following points all play an important role in tool performance and ignoring any one of them is likely to contribute to less than optimum results.

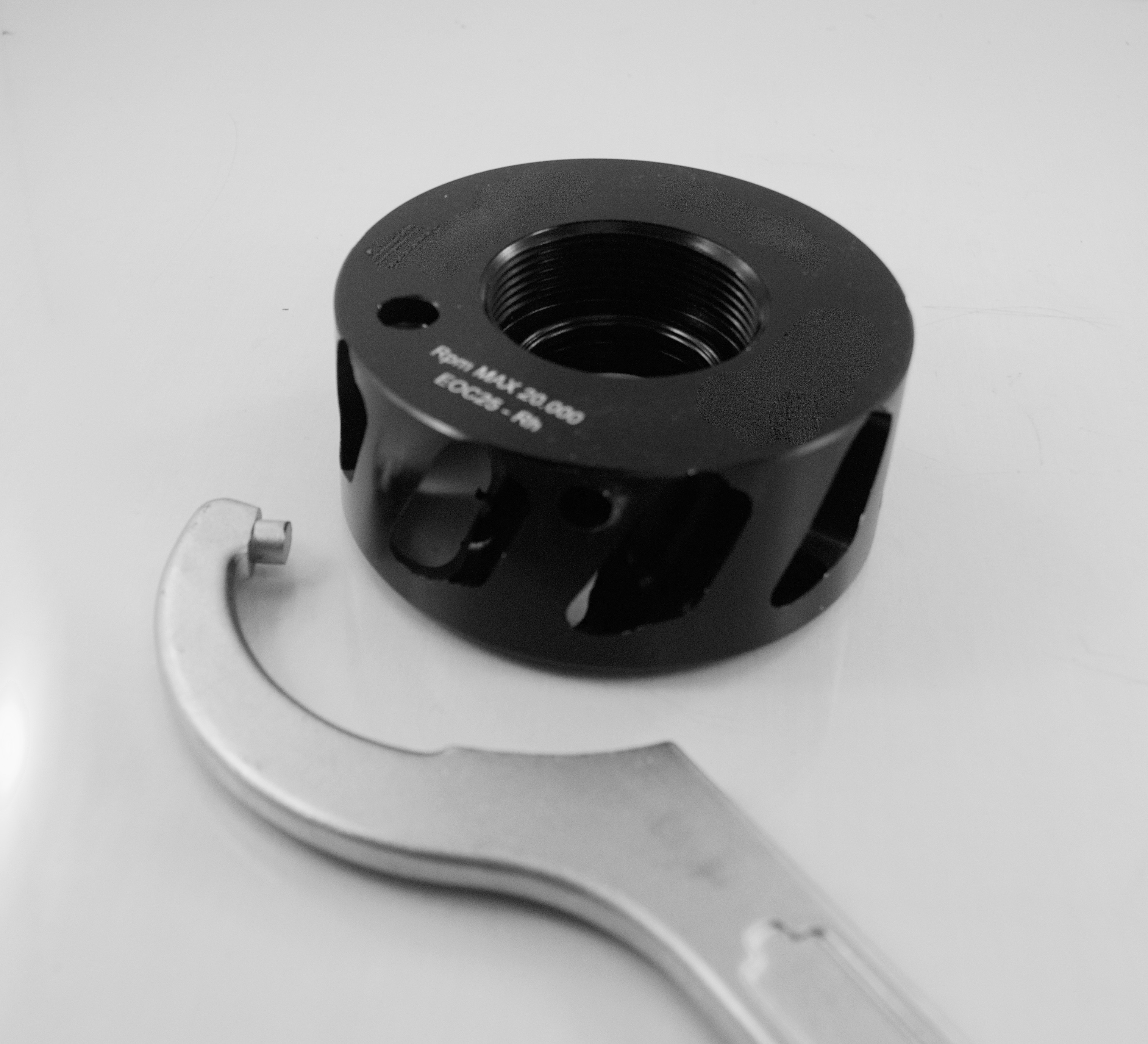

Tool set-up fixture (left) with torque wrench and collet key. The tool holder locks down into the setup fixture providing a solid base to tighten the collet nut to correct torque.

Tool set-up fixture (left) with torque wrench and collet key. The tool holder locks down into the setup fixture providing a solid base to tighten the collet nut to correct torque.Clamping systems

Imperative to cutting tool accuracy and performance is a precision balanced tool holder (collet chuck), preferably with a ball bearing collet nut that prevents tool slippage and provides an even distribution of clamping force between collet nut, collet and tool shank. Collet maintenance is an equally important aspect of tool performance. Collets should be blown out to remove dust with every tool change, and should be replaced about every 500 machine hours for optimum results.

Tightening the collet nut with proper torque is essential when a tool is set up for production. Incorrect torque is a major contributor to tool breakage, chattering and premature tool wear. With that being said, investing in a setup fixture and torque wrench, paired with tightening to correct torque based on collet style being used, is a small step that can lead to big benefits.

Tool selection

Solid carbide compression and spiral bits are the true workhorses and most commonly used tools. While they can look identical, they can be very different in their ability to obtain desired yield per cycle. It’s always important to select the right bit based on the material being machined.

Carbide spiral tools come in a variety of carbide grades dedicated to specific cutting tasks. Whether suitable for wood, plywood, MDF/particleboard with HPL or melamine laminate, choosing the right grade can save a lot of money and require less tool changes. Using a carbide grade for wood on melamine, for instance, will provide very poor results as the carbide is too soft for the very abrasive aluminum oxide content inherent in most melamine coatings. The difference in these carbide grades is in the binder material, cobalt. The more cobalt binder, the softer the carbide grade and the more impact resistant it is…however, on the downside, it wears fairly quickly. The lower the cobalt content, the harder and more brittle the carbide becomes, yet it becomes more resistant to wear, as evidenced by great results when cutting the abrasive aluminum oxide content in melamine. It is best to make sure the proper carbide grade is selected based on material being machined.

With high volume panel processing, it’s advisable to see if diamond tooling (PCD) is an option to reduce tool cost. With 2 and 3 flute PCD bits available now (they used to be limited to single flute tools on 1/2-inch diameter, thus limiting feed speeds dramatically), huge savings are often to be realized.

Material hold-down and dust extraction

Two facets that are often overlooked when analyzing tool performance are material hold-down and efficient dust extraction. Secure material hold-down is imperative to prevent movement of material and vibration during the cutting process. Efficient dust extraction is also key to ensuring dust is guided out of the cut and into the dust collection system. If dust is a problem, a dust extraction collet nut can help facilitate removing dust out of the cutting flutes so the tool does not overheat and is not recutting chips.

Proper chip load

Any sign of heat or dark discoloration in the flute of the tool is a clear indication of improper chip load applied to the machining parameters. Heat will rapidly cause the cutting edge of any tool (carbide or diamond) to deteriorate and become dull. Chip load is a calculation based on spindle rpm, feed rate and number of cutting flutes.

Increasing the number of flutes, such as going to a 3-flute cutter instead of a 2-flute cutter in hopes of getting a better finish is a fallacy. More flutes are only recommended when faster feed rates need to be achieved. The finish cut made by a 3-flute compression bit, under ideal operating conditions, will be no better than that of a 2- flute bit, run under its ideal machining parameters. For more guidance on chip load and tips on how to determine the best chip load for tool longevity, visit gdptooling.com/chipload-calc.

In summary, spending a little extra time to research cutting tool options based on material and application will go a long way to reduce tooling cost, waste and possibly even improve finish. Tooling cost is not determined by what you pay for the bit. It’s determined by the cost of panels cut or the number linear foot machined cutting the abrasive aluminum oxide content in melamine. It is best to make sure the proper carbide grade is selected based on material being machined. With high volume panel processing, it’s advisable to see if diamond tooling (PCD) is an option to reduce tool cost. With 2 and 3 flute PCD bits available now (they used to be limited to single flute tools on ½” diameter, thus limiting feed speeds dramatically), huge savings are often to be realized.

Source: Karin Deutschler is the president of GDP|GUHDO USA. For more information call 800-544-8436 or visit GDPTooling.com.

Have something to say? Share your thoughts with us in the comments below.