When I worked in the display industry, we did a lot of work with knock-down fittings. KD fittings allow you to build a project and ship it in a disassembled configuration; stacked flat panels, for example. When the pieces come out of the box, you then assemble them. One only needs to buy something from Ikea to know how that works. Almost everything Ikea sells comes packed in a box and needs assembly. Often there is an Allen wrench included to tighten the fittings or, perhaps, a Phillips screw driver is required.

This year at AWFS there were two things new in the realm of KD fittings that caught my eye. In my previous article, I introduced you to the AWFS Visionary New Product Award winner from Australian Company Joinlox (www.joinlox.com). Their product line is known as Striplox.

PANEL PROCESSING How to create a strong, totally concealed joining At AWFS, something new in the realm of ready-to-assemble fittings caught my eye: Striplox, which won a AWFS Visionary Award for its innovative rapid assembly system.

|

|

In this installment, I will be showing you the Torpedo CSIS system.

Stuck away in the far, back corner of the exhibit floor at AWFS was a small booth manned by Joshua Glasser. Representing Glasser & Associates of Martinez, CA, Joshua is bringing another Australian fastening system to the American market.

Personally, I love the back corners and small booths because it is often there that I find some of the most interesting information and innovative parts and pieces. Known as the Torpedo CSIS, this is a panel connector system that works with honeycomb panels, MDF, particle board/melamine panels, and solid wood.

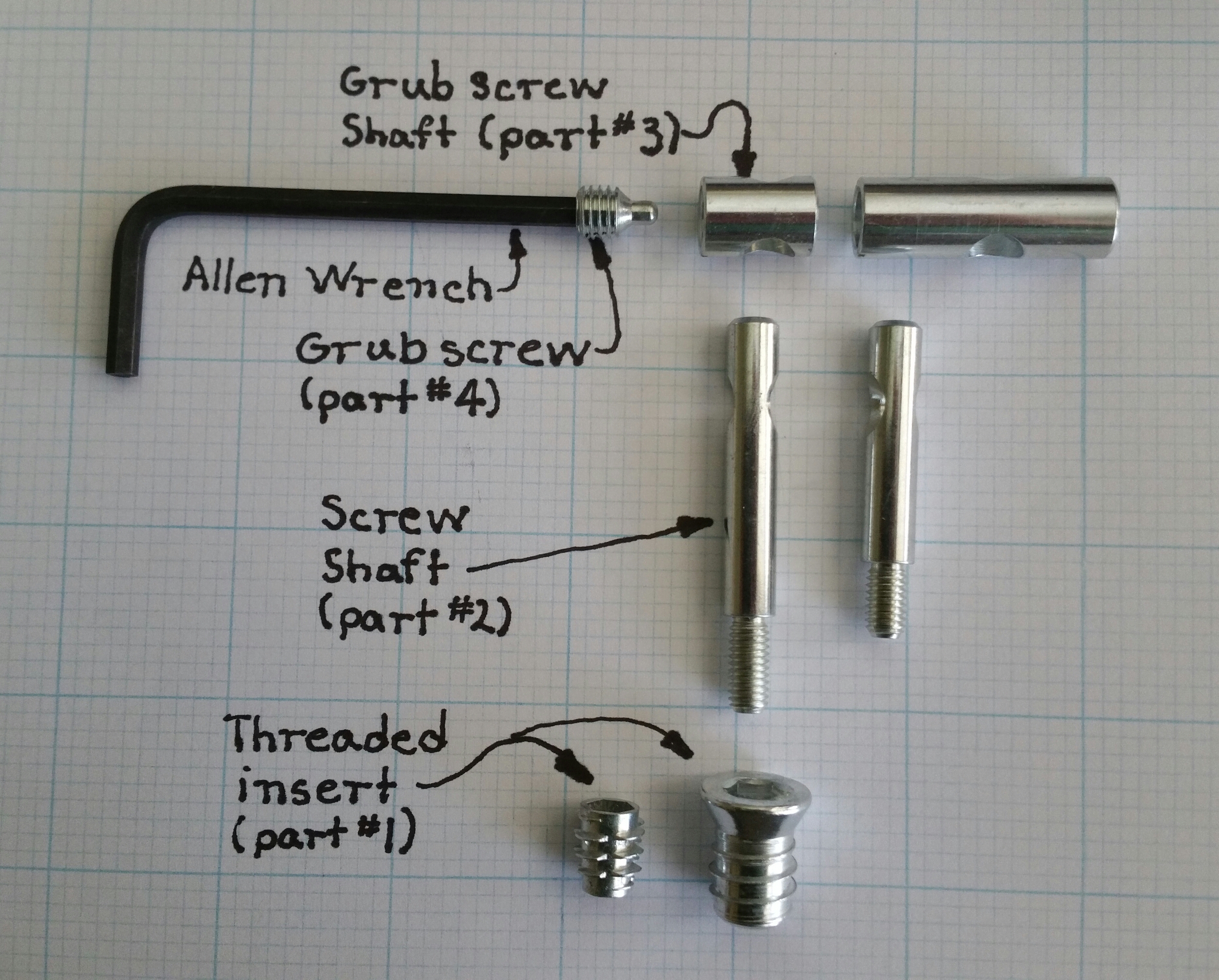

I have included four pictures of the parts of the Torpedo system. They will help you visualize how the following description works.

There are four parts to the system. A threaded insert (part #1) is installed first. It contains a female thread that will accept the screw shaft (part #2). The decision to use one or the other insert will depend upon the material into which the insert is placed. Think of this steel shaft piece (part #2) as being equivalent to a tenon or a draw bolt.

Torpedo CSIS system

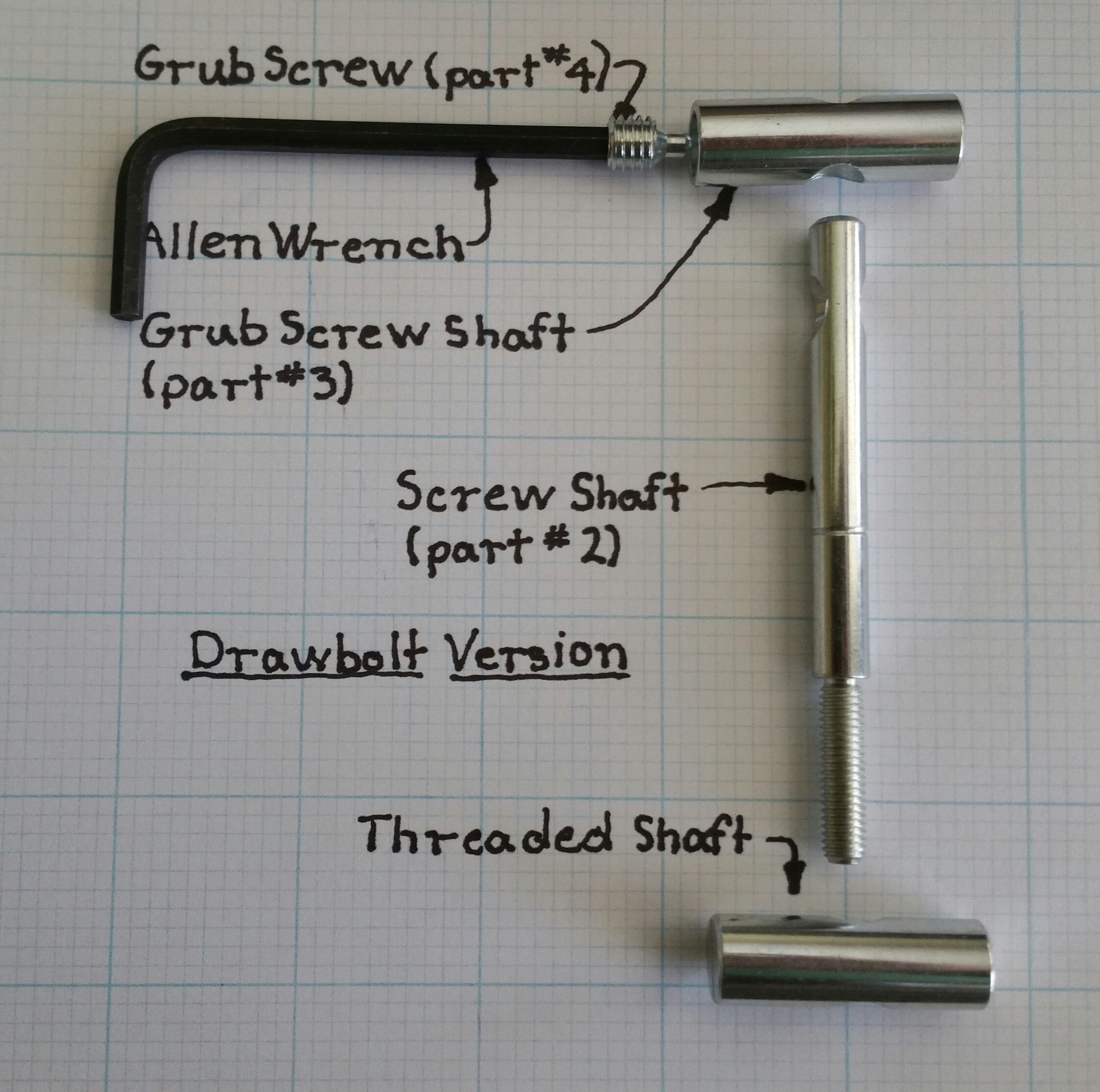

Torpedo CSIS systemHere’s where the uniqueness of the Torpedo CSIS comes to the fore. Enter the “grub screw” (part 4). The grub screw makes the fastening system work. The grub screw, a hex-socketed fastener, has a tapered, pointed end. That tapered, pointed end, when the grub screw is installed, goes into a corresponding tapered hole in what I described as the tenon (part #2). When it begins its contact with the tenon, the tapered, pointed end of the grub screw seeks to center itself in the corresponding hole in the tenon. The result is to draw both pieces of wood into a tension fit with each other. The result is tightness that is somewhat adjustable depending upon how accurately you drill your holes. However, the grub screw and its corresponding hole create a certain amount of tension by themselves regardless of hole placement.

The grub screw and the tenon meet inside of part #3. Take a moment to look at the two close-ups of the grub screw and the screw shaft (part 2). The inside of this grub screw shaft is drilled and tapped longitudinally so as to accept the grub screw. There is a hole through its side to accept the tenon (part#2).

Grub Screw

Grub Screw Screw shaft

Screw shaftAs you can see from my photo, there are different sizes of part #1, #2, and part #3 depending upon your needs. Also note that I have given you a close-up of the grub screw and another of the corresponding hole in part #2 into which the grub screw is inserted. Note that, as I stated, the hole in #2 is tapered. That taper on the screw and this hole is what creates the tension and draws the two halves of the joint together.

Draw bolt

Draw boltI have also included a photo of their version of a draw bolt. I like this piece of hardware. Having spent a lot of time doing countertops and other long projects, this draw bolt is adjustable and I like that feature.

Please feel free to look at https://www.youtube.com/user/TorpedoCSIS This link will take you to a number of videos that explain how this system works and how it can be applied to join any number of configurations.

The KD nature of this fastening system lends itself well to all sorts of applications where one would build and install the fasteners in the shop and then finish the assembly on site. And since the fastening method is a screw system, there are also applications where frequent assembly and disassembly are required. Then too, there are lots of examples in traditional furniture making where this system would save time and improve strength.

Until next time…spray on!

Have something to say? Share your thoughts with us in the comments below.